The Role of Relays in Standalone Engine Management

In the world of standalone ECUs, good reliable electrical power is king. The ability to supply, and switch various circuits quickly and reliably when needed is key to engine management or even body electrical management strategy. This management relies heavily on a crucial element: automotive relays. Although the use of electronic PDMs or “Power Distribution Modules” has risen quite a bit recently for good reasons, the traditional relay still has its place. In this article, we will delve into the specific role of relays in engine management, and their use in controlling components such as fuel injectors, fuel pumps, coils, cooling fans, and ECU power supply. We will also explore the ability of the Engine Control Unit (ECU) to control relays paving the way for precise control.

Electromagnetic Switching

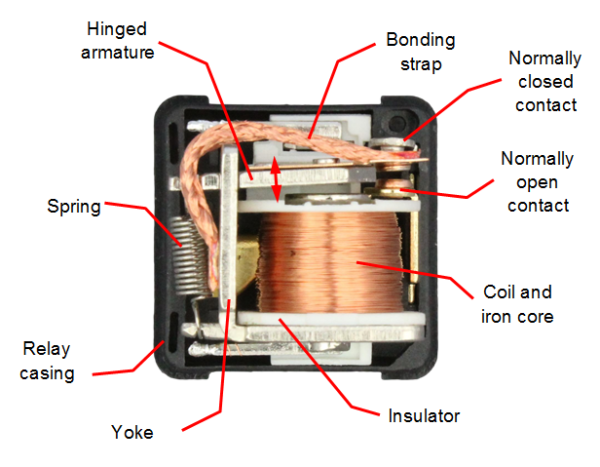

Automotive relays utilize electromagnetic switching to control the flow of current. When a low voltage is applied to the coil, it generates a magnetic field that attracts the armature. This action closes the contacts, allowing the current to flow through the relay circuit. Conversely, when the voltage is removed from the coil the spring force separates the contacts, breaking the circuit.

Types of Automotive Relays

The two major types of relays we’re going to run into are the stand electromechanical, and the solid-state types. While solid-state relays are becoming more and more common, by far the trusty electromechanical “clicker” style is what you’ll see most.

Electromechanical Relays: Electromechanical relays are the most common type used in automotive applications. They consist of a coil, an armature, and a set of contacts. When an electrical current passes through the coil, it generates a magnetic field that attracts the armature, causing the contacts to close or open. These relays are versatile and widely used for various engine management functions.

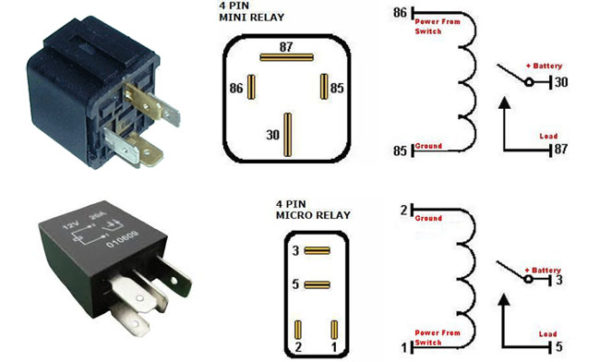

- Bosch Relay: This type of relay is commonly used in automotive applications. It features a standard pin layout and is known for its reliability and durability.

- Micro Relay: Micro relays are compact and are often used in modern vehicles where space is limited.

Solid-State Relays: Solid-state relays (SSRs) are a newer technology that offers advantages over electromechanical relays. Instead of using moving parts, SSRs use semiconductors to control the circuit. They provide faster switching speeds, higher reliability, and better resistance to shock and vibration. SSRs are commonly used in applications where precise control and long-term reliability are essential.

Relay Components

- Coil: The coil is an electromagnet that generates a magnetic field when an electric current passes through it. This field initiates the relay’s switching action.

- Contacts: The contacts are points that open or close allowing current to flow.

- Spring: The spring provides the necessary force to open or close the contacts.

- Armature: When the relay is activated, the armature is the component that moves and either connects or disconnects the contacts..

- Enclosure: The enclosure houses the internal components of the relay and protects against environmental factors.

Component Control

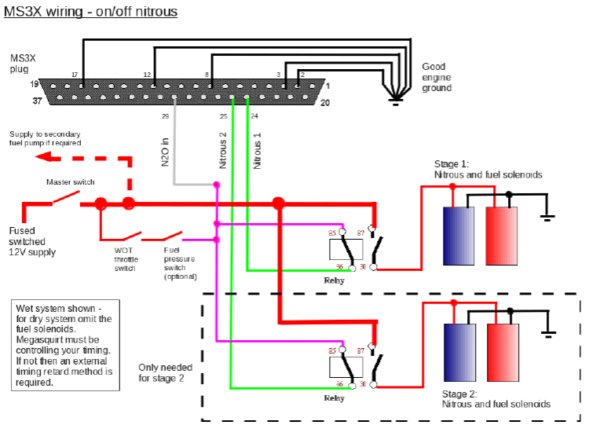

For any high-current device in a vehicle that can be switched on or off, it is advisable to use relay control. This can include nitrous solenoids, auxiliary pumps, oxygen sensor controllers, etc.

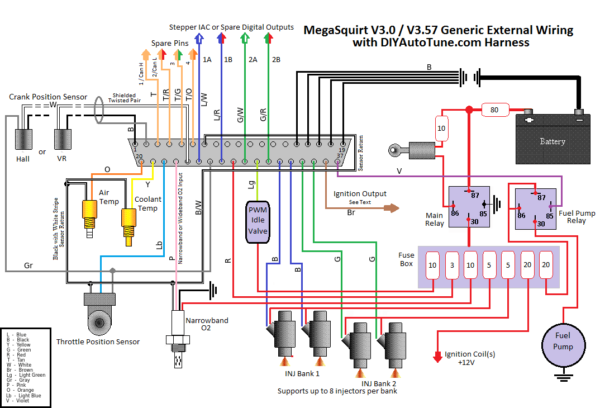

Fuel Injectors: Relays enable the ECU to control the power supply to the fuel injectors.

Fuel Pumps: Relays allow the ECU to activate the fuel pump when necessary. Importantly relays give the ECU power to shut off the fuel pump in the event the engine shuts down.

Ignition Coils: Allows the ECU to control when the ignition is powered up. This ensures the ignition system has its own dedicated high-current power supply.

Cooling Fans: Relays allow the ECU to activate the cooling fans as needed, preventing overheating and maintaining the engine within the optimal temperature range.

Advantages of ECU Relay Control

Having the ECU control relays can offer some excellent benefits. It allows us to use software to determine when a certain component receives power. The ECU can turn on things like cooling fans or secondary fuel pumps only when needed, and define under what conditions these things get powered up. This precision control not only adds some degree of safety but also allows far superior control over when these components come online.

Letting the ECU control your relays can also ease your wiring installation, and maybe even free up some real estate inside the cockpit. Now instead of having a physical toggle switch for every component, and wiring those switches back and forth through the firewall, the ECU can turn on each relay with just one wire for each component wired into its extra I/O pins.

Relays also act as protective barriers between the high-current devices and the delicate ECU. By isolating the ECU from potentially damaging current surges, relays safeguard the ECU and other engine components, enhancing their longevity and reliability.

In many cases, we want the ECU to apply ground to the control side of the relay. Using this method allows a measure of safety in that if a short to ground were to occur between the relay being controlled, and the ECU, we would just have a scenario where the component being controlled operates. If we were to send power out to the relay from the ECU and a short occurred, we now run the risk of damaging delicate ECU circuitry due to an overload condition.

Choosing the Right Relays

- Load Capacity and Current Rating: When selecting relays for engine management, consider the load capacity and current rating required by each component. Ensure that the relays can handle the specific current demands to avoid overloading and potential failures.

- Coil Voltage and Compatibility: The coil voltage of the relay should match the specifications of the ECU and other electrical components. Compatibility between the relay coil voltage and the system voltage ensures proper operation and compatibility.

- Temperature and Environmental Considerations: Engine compartments can experience high temperatures and harsh environmental conditions. It is imperative to select relays that are explicitly engineered to withstand these conditions for reliable performance and prolonged durability.

- Reliability and Longevity: Reliability is crucial in engine management systems. Opt for relays from reputable manufacturers known for their quality and durability. Relays with a long lifespan contribute to the overall reliability of the engine management system.

Remember to ALWAYS use the proper Wiring Techniques during installation. Proper wiring means secure connections and appropriately sized wire. Secure relays away from excessive heat, and vibration while also avoiding moisture when possible.

Conclusion

Automotive relays play a crucial role in engine management, providing precise control and protection for critical engine components. By facilitating the interaction between the ECU and components such as fuel injectors, fuel pumps, coils, cooling fans, and ECU power supply, relays enable optimal engine performance, efficiency, and longevity. The ability of the ECU to control relays using low current switching allows for precise coordination and real-time reaction, further enhancing overall engine management. Proper selection, installation, and maintenance of relays ensure reliable and efficient engine management operation for the long haul.

Join us next week as we dive into the software side of things, including how to use the advanced I/O capabilities built into the MegaSquirt ECUs. Be sure and sign up for our weekly newsletter to get all of our tips, tricks, product launches, and success stories.