Introduction

Standalone electronic fuel injection (EFI) has ushered in a new era of engine performance. Standalone EFI systems provide precise control over fuel delivery, and ignition timing resulting in improved power output and vehicle performance. While a lot of emphasis is placed on the design and implementation of EFI systems, the significance of proper ground strategies is often overlooked. In this week’s DIYAutoTune: QuickTip, we will delve into the importance of proper grounding for standalone EFI systems, with a specific focus on the significance of grounding for 5V-referenced sensors and the formation and prevention of ground loops. By implementing effective grounding strategies, you can enhance the performance and reliability of your EFI system.

The Significance of Ground Strategies

Grounding is a crucial aspect of any electronic system, and EFI systems are no exception. A robust grounding system provides a path for electrical current to return and serves as a reference point for voltage measurements. Without a solid ground, EFI systems can encounter a myriad of issues, including erratic engine behavior, poor fuel delivery, and even damage to sensitive electronic components.

Grounding for 5V Referenced Sensors

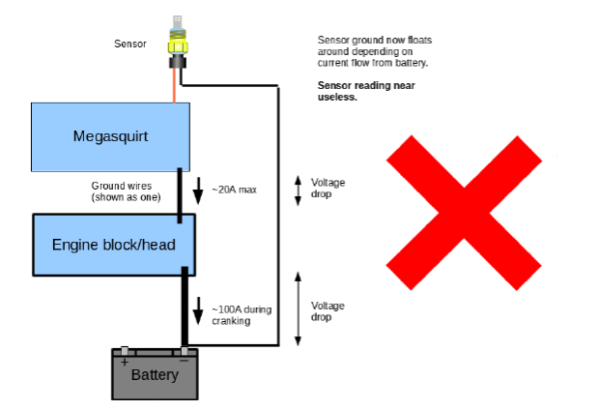

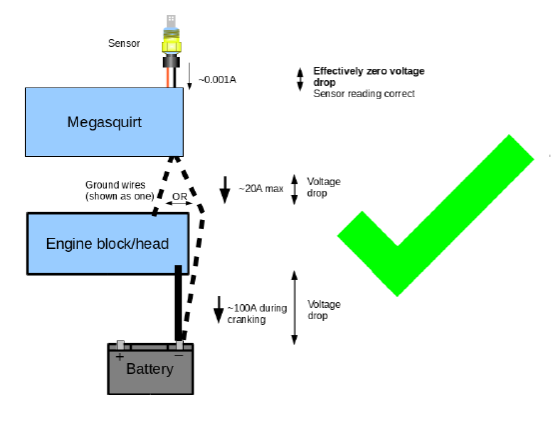

Proper grounding becomes even more critical when it comes to 5V-referenced sensors in standalone EFI systems. Sensors like intake air temperature, coolant temperature, and throttle position to name a few. These sensors rely on a stable and noise-free ground reference to provide accurate measurements. Inadequate grounding for 5V referenced sensors can result in noisy signals, leading to erroneous sensor readings and compromised engine performance. It is essential to establish a dedicated ground connection back to the “sensor ground” pins on the ECU, ensuring a clean and reliable signal transmission. Never ground your sensors to the cylinder head, engine block, or battery.

Ground Loops: Formation and Prevention

One of the most prevalent problems associated with improper grounding in EFI systems is the occurrence of ground loops. A ground loop arises when there are multiple paths for electrical current to flow. This can lead to noise interference, resulting in erratic sensor readings and disrupting the overall functioning of the EFI system. Ground loops can manifest as misfires, hesitation, and in some cases, they can even prevent the engine from running at all.

Ground loops can form due to various factors, such as improper grounding connections, shared grounding points with other electrical components, or the use of long and improperly shielded ground wires. It is crucial to identify and rectify the underlying causes of ground loops to ensure optimal system performance.

Preventing the formation of Ground Loops:

- Dedicated Grounding: The main grounds for the EFI system should have their own dedicated ground connection. This ensures a direct and isolated path for current flow, minimizing the chances of ground loop formation. All sensors need to be grounded back to the ECU’s “sensor ground” pins.

- Ground Isolation: It is important to avoid interference from other electrical components. This involves utilizing dedicated grounding points and avoiding shared ground connections with components like the ignition system or audio equipment.

- Proper Ground Wire Routing: Careful routing of ground wires is crucial to minimize the chances of ground loops. Ground wires should be kept separate from high-voltage or high-current wires to prevent induction and interference.

- Shielding: For sensitive components or wiring that is prone to interference, the use of shielding or shielded wire can help mitigate the effects of electromagnetic interference (EMI) and reduce the likelihood of ground loops.

Common Grounding Mistakes

To ensure the optimal performance of a standalone EFI system, it is imperative to avoid common grounding mistakes that can undermine its functionality. Let’s take a closer look at some of these mistakes and discover how they can be rectified.

Insufficient Grounding Points

Insufficient grounding points can lead to voltage drops, ground loops, and erratic engine behavior. To mitigate these issues, it is crucial to provide sufficient grounding points for all components, thereby ensuring a low-resistance path to the vehicle’s chassis. These ground points need to be clean of corrosion, paint, rust, etc. They also need to be kept tight, avoiding loosening from heat and vibration that will naturally occur in the engine compartment. Always use high-quality fasteners and be sure and check them regularly.

Improper Ground Wire Sizing

Another prevalent mistake is the usage of undersized ground wires. Ground wires are responsible for carrying the return current from the EFI system back to the battery or chassis ground. If the ground wires are too small in diameter, they can create resistance and voltage drops. To prevent this, it is essential to employ appropriately sized ground wires based on the current requirements of the EFI system. Following the manufacturer’s guidelines or consulting with an expert can assist in determining the correct wire gauge for grounding. Keep in mind that the ground wires need to be the same size or larger than the power supply wiring. This ensures that the entire circuit can handle the current expected.

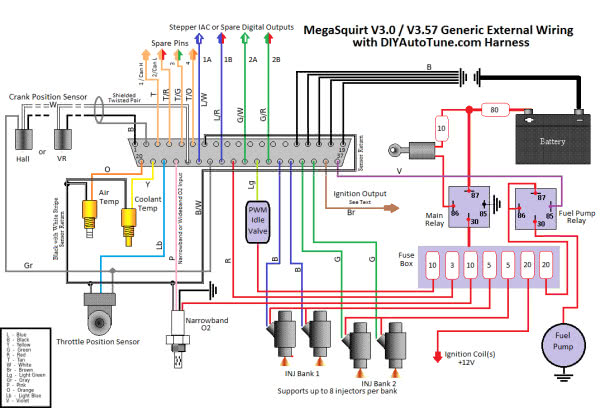

Grounding Rules in Megasquirt Installation

When it comes to Megasquirt installations, adhering to specific grounding rules is crucial for optimal system performance. These rules include:

- All sensors must ground at the Megasquirt: Connecting sensors to the Megasquirt ground establishes a centralized and consistent grounding point, minimizing the chances of ground-related issues.

- Ground the Megasquirt at the engine block/head using ALL available ground wires: Grounding the Megasquirt directly at the engine block or head using all available ground wires ensures a robust and stable ground connection. This approach reduces the likelihood of voltage drops and enhances the overall performance of the EFI system.

FAQs

Q: Why is proper grounding important for standalone EFI systems?

A: Proper grounding is vital for standalone EFI systems as it provides a solid return path for electrical current, helps eliminate ground loops and noise, and ensures accurate voltage measurements within the system. It significantly improves overall engine performance, preventing issues such as misfires and poor fuel delivery.

Q: How can inadequate grounding affect EFI system performance?

A: Inadequate grounding can lead to voltage drops, ground loops, and erratic engine behavior. It can result in misfires, hesitation, and inaccurate sensor readings, compromising fuel delivery and overall engine performance.

Q: How can I ensure proper grounding for my standalone EFI system?

A: To ensure proper grounding, it is important to provide sufficient grounding points for all components, use appropriately sized ground wires, and implement ground isolation. Following manufacturer guidelines and seeking expert advice can help ensure optimal grounding for standalone EFI systems.

Q: Can I share grounding points between my EFI system and other electrical components?

A: It is not recommended to share grounding points between EFI systems and other electrical components. Sharing grounding points can cause ground interference, disrupting the proper functioning of the EFI system. It is best to provide ground isolation for the EFI system by utilizing dedicated grounding points.

Conclusion

By implementing proper grounding strategies and avoiding common mistakes, you can ensure the optimal performance and reliability of your standalone EFI system. Take the time to establish dedicated ground connections, use appropriately sized ground wires, and prioritize ground isolation. By doing so, you’ll unlock the full potential of your EFI system and enjoy enhanced engine performance.