The guys at DD-EFI have done it again! With their Pro Dash’s ability to work as an I/O Expansion on MS3Pro, MSPNP, and any other MS2 or MS3 based products. Check out this guest blog post they have put together below. Which turns into a bit of a technical guide to help you know how to go Pro and expand your I/O!

-Jerry Hoffmann

Alright, hold on tight, we’re about to dive into the exciting world of Pro Dash I/O Expansion!

In our previous blog post (Modernizing with a PNP DD-EFI Digital Dash for your Megasquirt ECU), we discussed the Digital-Dash features and the capabilities of our Pro Dash series. But now, it’s time to get down to the nitty-gritty and talk about how to use the Pro Dash I/O like a pro.

Digital Inputs

Now, for Digital Inputs there are (7) of these that you can play around with. These bad boys are used for two options: triggering a function or indicating the input changing state. Think of them like the buttons on your TV remote that either change the channel or indicate whether the TV is on or off. All our dashes come preconfigured for turn signal and high beam indication, because let’s face it, you don’t want to be that guy driving down the road with his high beams on.

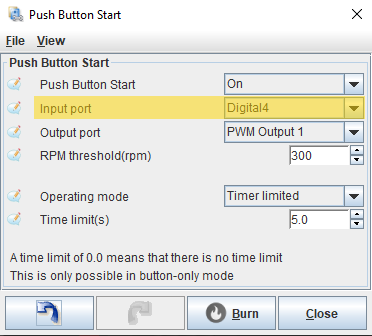

You also can use a digital input to trigger a function, like for example a Push Button Start. Just wire the digital input to a momentary push button. Your car starts like magic (well, actually it’s science, but you get the idea). And if you want to get fancy, you can use the On/Off images under the Dashboard Designer to display a turn signal arrow image. That way not only is you triggering a function, but you’re also indicating that the input is active. Double win!

Analog Inputs

You always need more sensor inputs, so we give you (5) more of these and (1) just for fuel level. These guys are used for variable sensors, like temperature and pressure sensors. But don’t worry, you don’t have to be a rocket scientist to figure out how to use them.

All our analog circuits are clamped at 5 volts, so you won’t have to worry about killing an input if you make a wiring mistake (although we don’t recommend making wiring mistakes on purpose, just saying).

If you’re wondering how to wire up a temperature sensor, it’s easy-peasy. They’re not polarity sensitive, but they do require that you apply the appropriately sized pull-up resistor to the circuit for proper functionality. The most common sized pull-up is a 2.49k ohm that is used for all OEM style sensors (with MegaSquirt). If you need to wire up additional sensors, we’ve designed a simple Breakout Board with DIP switches for applying the correct pull-up resistor. It’s like Legos for adults!

Transducers are also analog inputs, and they’re used to convert a physical measurement to an electrical signal, like pressure to voltage. These sensors have 3 wires, and the input voltage can vary by sensor type, but commonly they’re going to be 0-5V sensors. And just like with temperature sensors, quality is necessary for accurate readings, so we partner with Low Doller Motorsports to provide the best high-quality sensors at a great price. And who doesn’t love a great deal?

Outputs

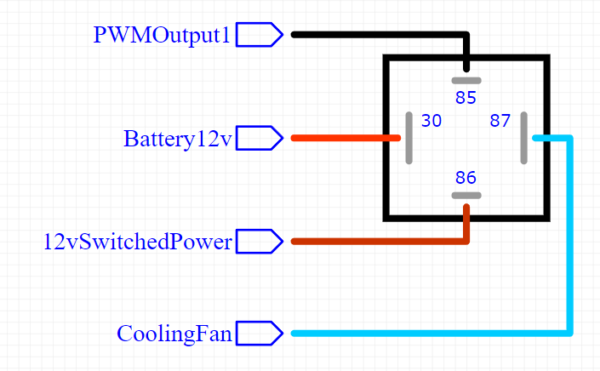

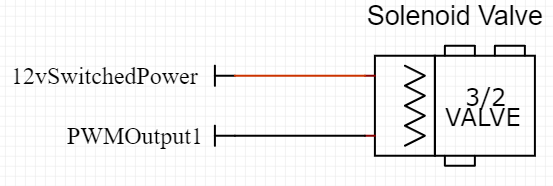

The Pro Dash provides (2) PWM capable outputs, that are capable of driving a load up to 5A each, which is pretty impressive if you ask us. And if you need more current capacity than this, you should use an interposing device like a 5 pin or solid-state relay depending on circuit usage. Because let’s face it, when it comes to electrical stuff, you don’t want to mess around.

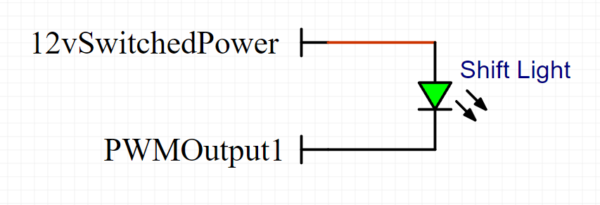

Before we jump in let’s just get one thing out of the way. The load needs to be supplied with switched (Ignition) 12v power. Otherwise, they will run when you turn the ignition off! This is not a mistake just how electronics work.

On/Off functionality is simple, you have up to three parameters to tell the thing to turn ON, unless you want to get lost in the loops…hahaha. You can control a small load up to 5A directly with the output. A larger load can be controlled by using the output to trigger a relay, the relay does all the heavy lifting like powering a cooling fan. The outputs on the Pro Dash pull the load to ground, meaning they provide a path to ground when the output is activated.

A small load (less than 5A) connected directly to the Pro Dash Output

An interposing relay for controlling a large load (greater than 5A)

Pulse Width Modulation (PWM) functionality is used to control a variable output. An example is ramping in a fan as temperature increases or creating a variable voltage output. For the control of a small load like an LED light, or a solenoid we can use the output directly. For larger loads like a cooling fan or electric water pump, you would use a solid-state relay. Unless you want to let the magic smoke out…. We don’t suggest that because = FIRE! The outputs on the Pro Dash pull the load to ground, meaning they provide a path to ground when the output is activated.

Solenoid valve connected to PWM Output

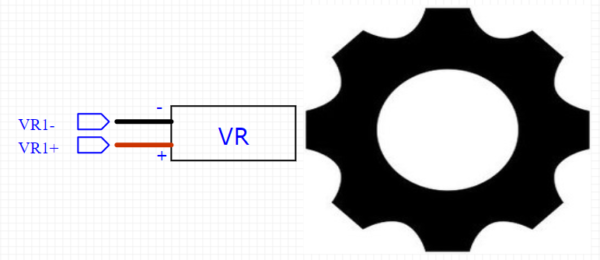

Speed Inputs

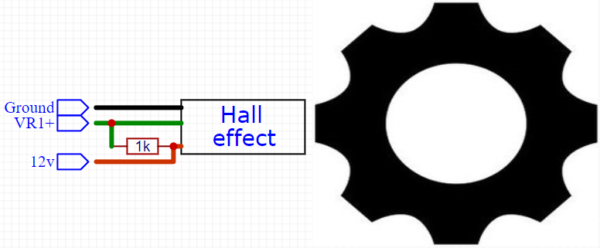

Now, there are (2) Speed Sensor Inputs available on the Pro Dash. We utilize a MAX9926 input circuit, so you get to pick either a VR or Hall effect sensor. A Variable Reluctance Sensor (VR Sensor) produces an AC waveform, the input measures the voltage between the two wires on the sensor. A Hall Effect Sensor is a three-wire sensor and produces a square wave, this type is better for applications with a low tooth count.

VR sensor to Pro Dash Speed Input #1

Hall effect sensors sometimes require a pull-up resistor if it doesn’t have one built-in. Both 5 and 12 volt can be used, but we suggest 12v for reliable triggering. Connect to VR+ input and leave VR- input disconnected.

Click Here to Check out the DD-EFI Pro Dash with I/O Expansion!

Opinions Matter

At DD-EFI we pride ourselves on good customer support, from easy-to-understand installation instructions to direct support with remote access capabilities. We stand behind our products and commitment to our customers. We want to hear from you the good, the bad, the ugly. Your feedback matters, it helps us provide features that you care about.

Customers enjoy being able being able to show off their installations, so join us on our Facebook Group. For more information on our Digital Dash’s, you can visit our website at www.dd-efi.com or email us at [email protected]

All DD-EFI products are designed and assembled in the USA!