UPDATE: Unfortunately, the DIYPNP product line has reached it’s end of life. This F.A.Q. page will remain available for archive purposes.

Is a DIYPNP fully assembled? Do I just plug it in when it arrives?

|

The DIYPNP ships in kit form and allows you to build a Plug-N-Play EMS for an incredible number of vehicles with more being added all the time. The DIYPNP is a brand new product line that bridges the gap between the MegaSquirtPNP, which is a fully plug-n-play MegaSquirt based product, and the traditional MegaSquirt kit. DIY preceded PNP in the name of the product specifically to help communicate that, it’s a brand new product aimed at the DIYer who would like to build their own PNP ECU that then plugs directly into the factory wiring harness of the vehicle. If you would prefer wiring to ECU building, then the traditional MegaSquirt ECU route you suggested may be more for you. If you would like a PNP ECU and we offer a MegaSquirtPNP for your vehicle then great, just pick on up, plug it in, and fine tune it! If you however prefer to leave your OEM wiring harness in tact and would like to build your own PNP ECU that plugs right into it, then the DIYPNP may be more your style. Not to mention we’ve added several extra hardware features to the DIYPNP. You can run full sequential on a 4cyl or semi-sequential on up to 8cyl’s with a very affordable plug-in module available here ($38 upgrade). You can run sequential COP ignition on your 4cyl even if it didn’t come with COPs from the factory. You have built in boost control, launch control, table switching, flat shift, and more. (See feature list for full details) One of the most exciting aspects of what the DIYPNP brings to the table is the simply massive number of vehicles you can fit it to, allowing you to build a fully plug and play EMS for more than 60 vehicles now, with more being added very soon.

|

What is a DIYPNP?

| The DIYPNP is a Do-It-Yourself Plug-N-Play Engine Management System. It is made up of three main pieces that allow for an incredibly flexible and modular system for building a plug-n-play EMS for a plethora of vehicles.

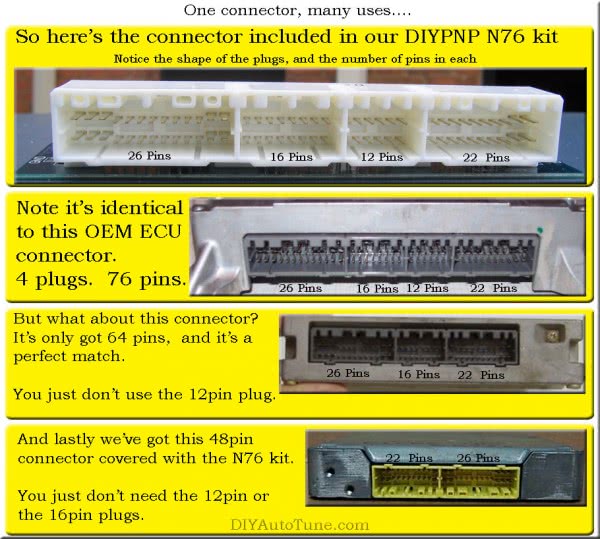

Mainboard – We’ve taken the awesome capability of the MicroSquirt Module, combined with the MS2/Extra firmware, and built out a mainboard that adds a very nice featureset including pretty much everything we get asked about on a daily basis by our customers. You’ve got dual ignition inputs and up to four ignition outputs (hi or low current, allowing for Coil-On-Plug for up to a 4cyl engine or wasted-spark ignition for up to a V8 engine. Distributor based ignition is of course supported as well. Knock control, boost control, 4 spare inputs and 4 spare outputs for driving fans, intake butterflies, on/off variable cam systems, whatever else you can imagine. There are more features too, check the features and documentation pages for full details. Connector Board – And then the last piece you need to know about is the connector board. This is a small PCB that slides into the same slot as the mainboard and lines up right next to it. It’s usually not much more than a breakout board for an OEM style connector that often fits a stack of vehicles as many of these connectors were used by multiple manufacturers, and often on multiple vehicles/engine families at each manufacturer. Sometimes we may fit an extra circuit on the connectorboard if we’ve found that the vehicles that use that connector typically need a particular circuit. An example of this is the Bosch Motronic 55pin connectorboard, which hosts a circuit to control the 3-wire IAC valve that is common in vehicles that use this connector.

The flexibility is massive. And if we didn’t include a circuit you want, we’ve got two large proto areas on the mainboard (one is under the uS Module) and in some cases there is a third proto area on the connector board if we had the extra space. |

Is a DIYPNP better than a traditional MegaSquirt EMS box for my needs?

| In short, a DIYPNP will do everything a standard MS2 will do, but has many extra hardware features built in to utilize features in the MS2/Extra firmware that normally you’d have to modify a standard MS2 to handle. In some cases those mods would be pretty extensive, but the DIYPNP makes it easy. Sequential injection and COP is a cakewalk. 2nd Ignition input, 4 ignition outputs, Boost control, launch control, flat shift, extra general purpose inputs/outputs, all built right in. There’s more too. Check the features list here.

And oh yeah, it plugs right into your factory harness and looks clean too ;). |

Do you offer a DIYPNP kit for my car/engine?

|

We’ve got a fairly long list of the vehicles and engines the DIYPNP kits we currently offer will support on our Available Models page here. Keep in mind that just because your vehicle is not on the list does not necessarily mean that it won’t fit, it might just mean we missed your car and didn’t realize we need to add it to the list. You’ll notice on that page that there are images of the connectors included with each kit, take a close look. If the connector will fit your car then there’s a very good chance we can help you out. Shoot us an email and we’ll help you confirm the ignition system on your vehicle is supported, and we’ll add your application to the list of supported vehicles as well. Keep in mind when you’re comparing your connector that sometimes we’ll offer a connector that has more outlets on it than you’d need for your car. For example, the 1990 Miata only uses the 22pin and 26pin plugs of our N76 connector, leaving the 12pin and 16pin plugs open. The connector is a perfect match though. This will be the case with other connectors as well as we will always base our kits on the connector that fits the broadest number of vehicles possible. See the image below for an example of this.

|

What will be included in my DIYPNP kit?

|

All of the parts needed to build your DIYPNP EMS will be included.

|

Is the assembly difficult?

|

Difficult is a relative term, but for most even semi-mechanically oriented enthusiasts/racers, these kits are fairly simple to assemble. In many ways they are far simpler than a standard MegaSquirt EMS to assemble and get up and running on your vehicle. The part count is much smaller as compared to a standard MS kit, and there are not any components with tiny little closely spaced legs to give you fits. What remains after the basic assembly is running a series of jumper wires from the mainboard to the connectorboard, basically connecting the 12v hole on the mainboard to the pin on the connectorboard where your stock ECU provides 12v. Then you do the same for ground. And for each sensor. Beyond this there are a few jumpers to set to enable the ignition configuration needed for your vehicle, and a couple resistors to install if needed for your ignition system. To the experienced MegaSquirter, this is a breathe of fresh air simplifying the process greatly. To someone new coming into the process it might still sound a bit confusing, but don’t worry– that’s what we’re here for. We’ve got an incredible support team that’s here 40+ hours a week for you. That said, we’re fully intending to work our way through the application list, using local volunteers who bravely offer up their cars, and working out the exact pinout and ignition configuration you’ll need for a particular vehicle. We’ll be documenting these and posting the information on this site. As a part of doing this for these volunteers, we’ll also be getting the car started for them, and if they so choose, tuning it for them. So we’ll have at minimum a startup map available, and in some cases a base map that is well tuned for the test car that we were brought, though it’s mods, and therefore mapping needs, may differ from your own a bit. |

What if I’ve never soldered anything before?

|

You can do it! It’s really not that hard. There are a few basic rules:

The maker of that video (linked from Youtube) also offers very affordable toolkits with everything you’ll need to start soldering. |