Lots of pictures here. I hope to have it back this week….

Shortened control arms to bring the tires inside the fenders. Also relocated the front attachment points on the tension rods to add some caster.

Tubing to protect the fuel lines from the fuel cell box up to the engine bay. There will be 1/4″ plate around these where it passes the bellhousing. That piece is made and will be welded in this week.

Cardboard mockup of the dashboard

Aluminum dashboard complete. Notice the touchscreen dash display. We might end up running a different piece (possibly an android tablet) but this is what it will look like more or less.

Roof rails in process and then the final product in place, perfectly parallel and straight.

What’s this huge ‘stovepipe’ looking thing running across the passenger floorboard you might ask?

Why that would be a 5″ exhaust conduit running through the floorboard. What? Doesn’t everybody have one of these?

This will allow me to get the exhaust out of the back of the car, and to run as large as a 4.5″ exhaust pipe through it. Where it exits just in front of the rear axle I’ll just need a slight bend and short run under the axle and out the back of the car. Most people take the ‘easy button approach’ on this and just dump it out the fenders, which looks cool, but aerodynamically sucks. And blows. At the same time. I’ll heatshield cover the actual exhaust pipe that is passed through this conduit so that I don’t have a 800degF+ pipe running across my floorboard inside the cabin.

We had to revisit the tunnel height and add a few inches to insure I’d never have trouble with driveshaft clearance regardless of ride height. We were afraid it’d be tough to make it look right, as the cage had to be cut into to make it happen, but it looks like it was designed to be there from the get-go! This is .120 wall tube material, same as the cage.

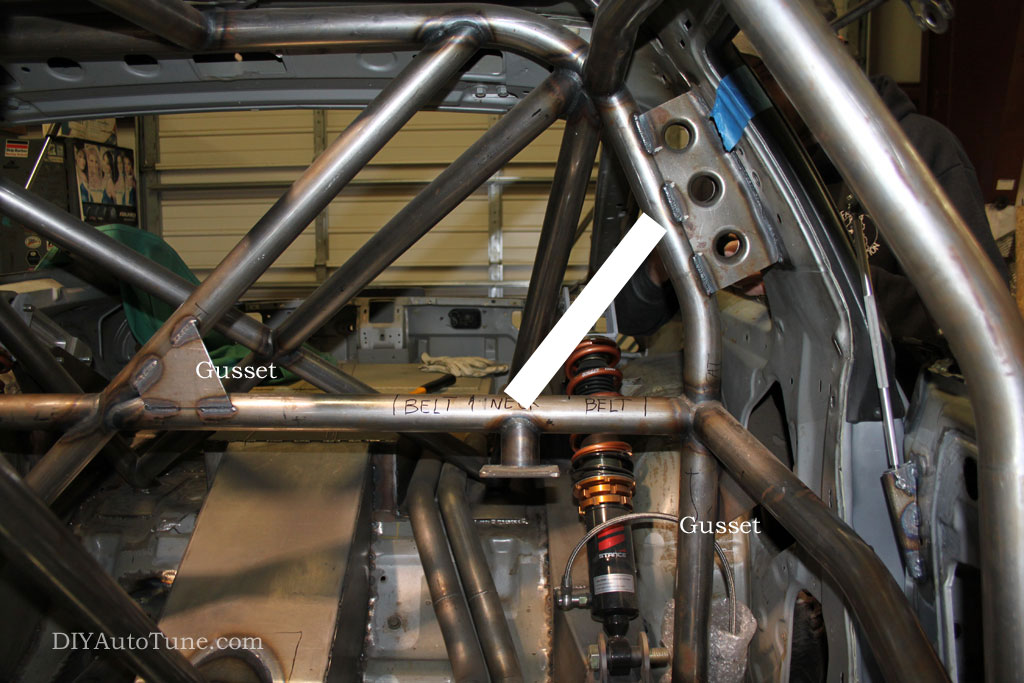

Trying to figure out the best way to gusset the shoulder bar to the main hoop here behind the drivers seat. The plate type gussets won’t fit with the seat belts being wrapped around the shoulder bar, as at a minimum they would provide a cut point, if the belts would fit at all on the one side (behind the left shoulder, right side of this pic).

I’m thinking a tube gusset on the top side of the shoulder bar, from where it’s marked ‘neck’ which will be in between the belts, up diagonally to the right into the main hoop where it ties into the body. Trying to ensure that will work now with the SCTA/ECTA officials.

Something like this:

Click for a closer look— Any where is says ‘Gusset’ without a question mark is pointing out an existing 1/8″ plate gusset as per the rulebook. The white diagonal bar (marked Gusset??? in one pic) is where I’m considering putting a tube gusset, same size tube as the cage probably which is 1.75″ diameter .120″ wall DOM tubing.

Need to determine for sure that meets the rules, and that I’ve got adequate gusseting throughout.