The car finally made it back to our shop last month, and once we wrapped up a few events we had scheduled I got straight to work on it.

At this point, I’ve installed a ‘shakedown engine’ which is a bone stock intenal 2JZ-GE from an NA MKIV Toyota Supra. I’ve fitted a SupraStore.com ‘Quicksilver’ exhaust manifold and a Precision 6766 Turbo with 1.15 A/R that should be good for 930+ horsepower. I’ve also fitted a Swift Racing Technologies (SRT) 2JZ-GE intake manifold, which is a very nice piece BTW.

The Gforce GF4A transmission is currently installed so I could measure and make up clutch lines for between the Tilton Hydraulic Throwout Bearing and the Tilton Clutch pedal assembly with 3/4″ Master Cylinder. I removed the brake pedal from the Tilton pedal-box as I’m not going to run one, instead we’ll be running a level on the left side of the drivers seat controlling only the rear brakes, there will be no front brakes. The parachute is the main braking system anyways… besides, this is about going fast, who needs brakes anyways?

I need to pull the trans and install the clutch lines (they can’t be reached while the trans is installed) and then reinstall the trans.

Dynotech Engineering jumped on board with us and they’re cranking out a new driveshaft for the car. They recommend a 3.5″ Chromoly shaft with Billet Mark Williams yoke. We provided all measurements using their easy to fill out order form and we should have the shaft here next week.

We’ll be running a set of Bosch Motorsport 115lb hour injectors which will work perfectly for us on gasoline. One day down the road we’ll run methanol, and at that point we’ll need more injector (and a couple other changes)…. but these will be perfect to chase the F/BGC record we’re after now.

The Shakedown Engine

The motor that’s in the car now is purely there for shakedown. We’ll build the wiring harness and tune it in on our in-house DynaPack dyno, running race gas and probably about 10spi of boost assuming the 46mm Precision Wastegate can hold the 6766 Turbo down to that without creep. I think we’ll be ok there…

The Race Engine

Ball Engines in Lilburn, GA is putting together the longblock for us. Rafael at Rev Valves did the porting work on the head and installed a Rev Valves valvetrain (dual springs, titanium retainers, +1mm oversize valves on the intake and exhaust, etc). The head will be here soon and delivered to Andrew Ball @ Ball Engines for longblock assembly.

We had the crankshaft lightened about 10lbs and knife-edged, as well as destroked it 2mm so that we’ll stay within the displacement limitations on the class (3.014 liters) after cleaning up the bores by opening them up .5mm (and we can go as far as 1mm over and stay in our displacement class).

GSC S2 Cams are fitted to the head which should be perfect for the 900whp goal we’re after.

Mahle Pro Series pistons will be mated to Carillo H Beam Rods with a oh-so-sexy PowerHouse Racing Billet Dry Sump system in the basement.

Installed the Precision 46mm Wastegate, and built turbo oil feed and drain lines.

Trans is in, so are the fire bottles (with half of the fire plumbing completed) and the parachute lever is mounted and cable run.

Window Net. Check.

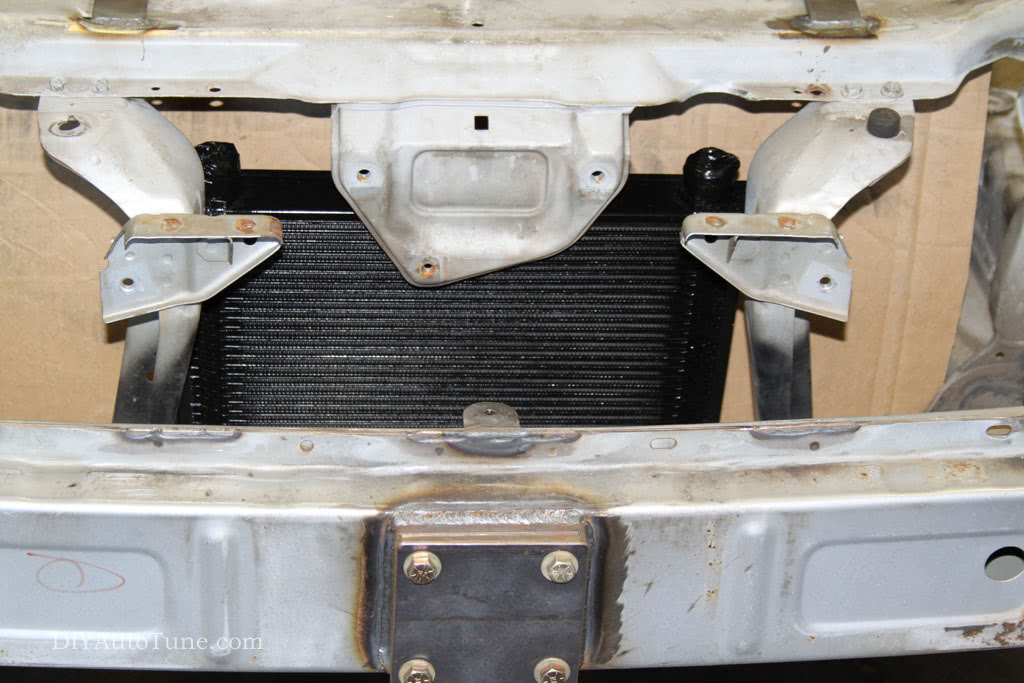

Radiator and oil cooler are placed in position, ready for permanent mounting and plumbing.

Almost ready to wire and fire!

W2A Intercooler and ice tank

Rhodes Race Cars is building us a custom 15+ gallon ice-water tank with internal 3700gph pump, and I’ve ordered a 6″x6.5″x15″ Water-to-Air Intercooler to test with that may or may not be our final solution. I think if we do a little fab work up front, replace the front bumper with a tube for instance, that we can fit a much bigger intercooler if need be. We’ll test on the dyno and see if we need to. My goal is to have -below ambient- intake air temperatures at the end of the 5 mile course.