It’s been way to long since I’ve offered an update… so here we go— you can click on any of this images for a closer view.

I’ve got wheels! OK, so they’re not mounted on anything structural yet, but he’s a mockup on a junkyard 10-bolt we’ve got under the car right now. Turns out a G-Body 10-bolt fits perfectly under this car, at least if you’re running 15″ x 4″ wheels and 25″ tall by 4″ wide tires…

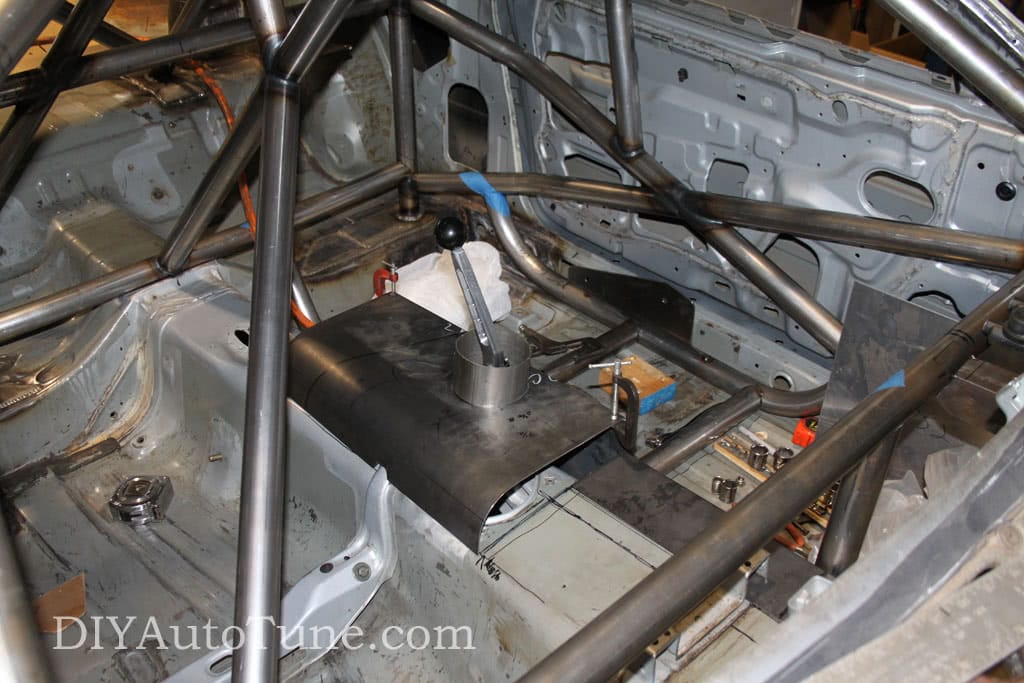

Cage is pretty much complete, we’re fine tuning the seating position. I fit in the car, but it’s tight. We’re trying to lay the headrest on that seat back a little which will help a bit. It also gets my head lower below the top of the cage. I fit inside the outer plane of the cage, but I’m just above the inner plane of the cage, meaning my helmet comes up a bit above the bottom of the bars, but not outside the top. We’re bring that down a bit, but it’s tight in there. Pardon the image overkill here, I’m sending a link to this page to the tech official that’s been helping me out, Steve ‘Kiwi’ Davies, to ensure all looks well with the current seating position and clearances between the tubes and my mellon. Scroll down to the next section if the pictures of me behind bars gets boring ;).

Trans tunnel is reconstructed but not finish welded yet after chopping it up to make room for the G-Force GF4A transmission.

Motor mounts to put the 2JZ engine into this S13 240sx are done, and look dead sexy and tough as nails…

The engine is back out of the car. Block and crank are at the machine shop, head is shipping out tomorrow. Block checked out good, no bore needed, just a simple hone. Crank is being knife edged and lightened as much as possible. Head is going out for port & polish work, oversized valves, etc. After the head work is done the head goes to Carillo so they guys there can 3D model the combustion chamber and see how much piston they can stuff in there. The closer to 14:1, the better. Not sure what we’ll be able to get yet.

Diff is on order, should be here in about 3 weeks. The guys at Fat Cat are using a different 10-bolt diff for mock up now and going ahead and building out the 4-link and panhard bar. Here is the first evidence of this, the pickup points and cutouts for the 4-link rear suspension. This will all be boxed back in once complete.

Fat Cat should be cutting out the rear soon and mounting the fuel cell. Once the fuel cell and surrounding structure is built the parachute mount will be built.

I’ve got someone lined up to build a fiberglass nose for the car with air dam. I’ve got to order a nose as a starting point…. in fact I need to go spec that and order it today if I can swing it….

The clutch/flywheel we were hoping to use sadly will not fit, it’s too deep for the bellhousing we’re using. So I’m trying to source a clutch/flywheel that will work on this wacky combination of parts that I have.

The bellhousing we got to mate that Toyota engine with the G-Force trans doesn’t fit right either. It’s off in a couple of dimensions, not allowing the input shaft of the transmission to engage the pilot bearing (too deep), and it’s a bit off center which effects the alignment of the crankshaft and input shaft on the trans. We’re sending it back to Quicktime to correct it with dial indicator markings 360* around the bellhousing every 10* noting on it so they can make it right. Turns out we’re one of the first three people to purchase one of these, it’s a brand new product, and we’re sorting out the bugs it appears.

So.. basically I’m constantly solving problems and finding parts, and my fab shop is doing much of the heavy lifting. As much as I’d like to be doing more of it there’s no way it would happen in time if I was doing so while I’m also trying to keep this business going and growing, so I’m glad to have their help.

That pretty much sums it up. I’m still fairly confident we’ll make SpeedWeek with the car, but we have a lot left to do. My fallback plan is World Finals in October, but I’ve got my sights on SpeedWeek…. I think we’ll make it….