With the fuel pressure failsafe feature in the MS3X and MS3Pro, losing your fuel pressure doesn’t have to mean losing your engine. Instead, the MS3 can detect if you’ve lost fuel pressure, and trigger an automatic limp home failsafe. The MS3 will first activate a spark cut, while still running fuel to cool the engine. It then cuts fuel until your engine RPM and load drop to a safe value where the engine is at little risk for detonation.

Here’s how to make this work. You’ll need to install a fuel pressure sensor to use this feature.

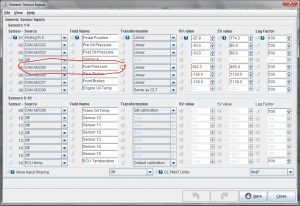

First, you need to set up the fuel pressure sensor under Advanced Engine -> Generic Sensor Inputs. These settings let the MS3Pro know which input pin or remote CAN input is being used for fuel pressure, as well as the calibration data for the sensor you’re using. The fuel pressure needs to be scaled for kilopascals (kPa), although you can use either an absolute or gauge pressure type sensor.

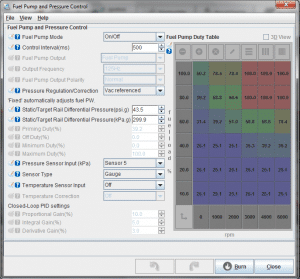

Next, you’ll configure how the fuel pressure regulation works under the Fuel Settings -> Fuel Pump and Pressure menu. You’ll need to enter several key settings here:

- Whether your fuel pressure regulator is vacuum referenced, or uses constant pressure

- Your base fuel pressure

- Which generic sensor number is being used for fuel pressure

- Whether the sensor being used is an absolute pressure sensor or gauge pressure sensor

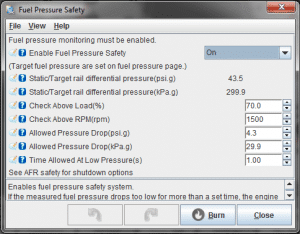

Once your fuel pressure settings are complete, go to Fuel Setting -> Fuel Pressure Safety. Here, you’ll turn on the fuel pressure safety feature, as well as setting how much fuel pressure drop is allowed and how long to allow the pressure drop before activating an engine shutdown. In most cases, you’d set the time allowed to be just long enough not to be affected by noise or jitter in the fuel pressure signal.

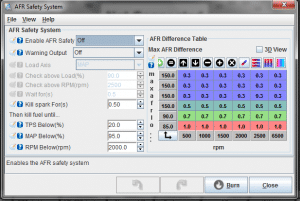

Once this is done, you have one more screen to set up. This one’s under Fuel Settings -> AFR Safety. Here, you set how long to apply the spark cut before the fuel cut engages, and at what points the MS3 can turn the fuel back on.