Project Goals

- To learn, first hand and hands on, all that can be learned about the pros/cons of carbs vs. EFI. What manifolds work best, what off-the-shelf TBI systems work best.

- To be completely non-biased in our approach, sure we’re EFI guys, but if the carb shows a pro over EFI somewhere, great! I’m confident enough in our products that I think the EFI pros will be there, but the facts will be found and told here.

- Determine how we can help our customers that want to convert to EFI do so. We’ll do this with cost, performance, and ease of installation in mind, very likely from the perspective of compromise (cost/ease of installation vs performance), but likely also from each extreme as well. This means we’ll start with the most affordable, simplest solution, which could compromise overall performance somewhat. Then in time work up to a full scale performance oriented system.

Expectations

- I’d expect the carb could potentially have an edge with peak horsepower at WOT. Rumor has it anyways…

- I’d expect EFI to edge out the carb pretty much everywhere else. This would include better emissions, better fuel economy, better drivability including cold start. Lastly, It’s possible we’ll see better power ‘under the curve’ (away from peak) with EFI.

Questions

- What air/fuel distribution issues might we run into with the simplest of carb-to-efi conversions, a throttle body injection (TBI) setup?

- What air/fuel distribution issues already existed with the stock carb and manifold? This is a question that is often not asked…

- Are we better or worse off with cylinder-cylinder air distribution with the carb or TBI on the stock manifold?

- Does this improve or worsen with an aftermarket intake manifold that’s original intention was for carb’d vehicles?

- Does a single plane or dual plane manifold better fit a TBI setup?

- We’ll be testing with the Edelbrock Performer (dual plane) and Torker-II (single plane).

Test Process and Interpretation of Data

Prior to testing a basic tune-up was performed including spark plugs, plug wires and oil change.

Dyno: DynaPack 4022 Dynamometer. Pulls will be started at 1800rpm to get the T350 tranny in 3rd gear during the pulls. Kickdown cable disconnected to keep it there. The car makes more torque right off the line, but on a dyno with an auto tranny it’s tough to keep it in high gear to test down there. For consistencies sake it’s better to start at a higher RPM and hold in it high gear for the pulls.

More notes on the dyno results— During Test1, Test2, and Test3, the results on the dyno are comparable with each other, but not directly comparable with the later results from Test4 on unfortunately. Due to this car not have a tachometer, and our not having the EMS wired up during these tests to accurately display a tach signal, the dyno was miscalibrated for the wrong gear ratio during these pulls. Basically— when we bought the car we were told it had a 3.73 rear end, so we trusted this and that’s the number the dyno used to calculate RPM on the pulls for those early tests. After Test3 was complete, we tested this on the dyno since we had the MegaSquirt hooked up and could monitor the actual RPM digitally and properly calibrate the dyno to the axle ratio— turns out this car does NOT have a 3.73 axle, it’s actually a 2.59! (Dyno measures it as 2.602, GM offers a 2.59 though). This means on the earlier pulls (Test1-3) we were pulling the car from a lower starting RPM than we intended to, out to about 3900rpm at the top of the pulls (where the charts read 5500 in error it’s really at about 3900)! This sucks, but we’ll just have to move on. Keep in mind the Tests1-3 are directly comparable. Test3 and Test4 are the same exact car configuration, but Test3 is with the dyno mis-calibrated for the wrong axle ratio, and Test4 is configured correctly. That gives you a way to get back on track. Use the Test1-3 results simply as relative comparisons to each other only. Going forward from Test4 onward the tests will be run consistently with the proper axle ratio and provide true HP/TQ figures at accurate RPM. It’s also at this point we’ll be starting the pulls exactly at 1800rpm, and taking peak torque readings at 1900rpm since it’s sloping off right from the word go, yet we don’t want to take a peak reading at 1800 where the dyno is holding it steady. If we do anything radical enough to change the torque curve to where this isn’t the case and it peaks later, then we’ll report the torque peak for where it is, but we’d have to go into the motor to do that and that would likely be far along into this testing (dare I say playing?).

Highway MPG: Average speed 70mph. Windows down. 35psi in tires. 60.2 mile round trip. Same route every test.

Wideband O2: Unless otherwise noted we’re monitoring a single bank of cylinders, the passenger side (2, 4, 6, 8) using an Innovate LC-2 with a fresh sensor, freshly calibrated. On some tests we may install an Innovate LM-1 in the second bank so we can watch and compare both banks of cylinders. The wideband will establish our average air/fuel ratio (AFR) for all cylinders (assuming the second bank is roughly the same as the first which is fairly safe unless the EGTs show us it’s not, and then we can add a second wideband). This average AFR for all cylinders is just that, an AVERAGE for all cylinders, meaning some cylinders are richer, and some are leaner, and we’re reading it after the collector and therefore getting an average. The individual EGT probes will help us to know which cylinder is leaner and which is richer.

Exhaust Gas Temperature (EGT): We’re monitoring all 8 cylinders using a pair of Innovate TC-4’s (Note – we have discontinued carrying the TC-4 and replaced it with the eight channel CAN-EGT) and 8 of our ‘Black Stinger’ Open Element EGT Thermocouples. What we’re looking for here is the temperature variation between the cylinders. Without getting into all the details of EGT tuning on this page, since we’re aiming to keep the AFR’s well south of 14.7:1, then that means the hotter the EGT, the leaner we are, or the closer to 14.7:1 we are. And at WOT under load, 14.7:1 is WAY TO LEAN. So what EGT is going to tell us is which cylinders are breathing better than others with the different carb/manifold setups, and eventually with the different EFI/manifold setups. It will help identify if there are air/fuel distribution problems to certain cylinders and/or atomization issues to certain cylinders. The cylinders that are getting more fuel mixed with the air will run cooler. The cylinders that are getting less fuel mixed with the air, and therefore are running leaner, will be hotter. The possible exception to this would be if they ran SO lean that they got past where peak EGT is (around 14.7:1) and started getting cooler again. I think we’ll be keeping it south of 14.7:1 on all cylinders though and the wideband results combined with the EGT results will help us to know this.

It stands to reason that on a wet manifold engine such as a carb’d engine or a TBI EFI engine, where the fuel and air mixture flow through the manifold together, that you have two main issues. Airflow being one, and atomization being the second. There are others but we’ll focus on these for now. Both of these issues can effect the ultimate AFR that reaches a given cylinder but one may play a larger role. Ideally you’d have even airflow to all cylinders and the fuel would perfectly atomize reaching all of those cylinders evenly. We’d see nice even temps across all the EGT probes. What may happen though is more air may flow to certain cylinders than others. Here’s where a wet flow manifold is unique from a dry-flow such as used in multi-port EFI. In multi-port EFI you’re just flowing air through the manifold, hence it’s ‘dry-flow’. The fuel is injected in the manifolds runners just before the valves and spends very little time in the manifold itself. So really it’s not 100% dry, maybe 90%. But the bottom line is atomization in the manifold itself is not as big of an issue. Even airflow to all cylinders in all conditions is the big issue. In a wet-flow manifold however, you have both of these issues, but theoretically at least, even airflow may be the lesser of the two problems.

If Cylinders 1 and 2 are getting more airflow than 3 thru 8 in a dry flow (MPI EFI) manifold, but the fuel flow is the same to all cylinders, then cylinders 1/2 are going to run leaner than the rest. If the same situation exists on a wetflow manifold with a carb or Throttle Body Injection (TBI) and 1/2 are getting more air than the rest of the cylinders, but the atomization of the fuel with all of the air in the plenum is evenly mixing fuel with all air entering all runners, then since it’s a wet flow manifold those cylinders should also be getting more fuel to go with that air, and should be getting a proper air fuel ratio, and the consequence of their getting more air/fuel is more power from those particular cylinders, not a dangerous lean condition. On a wet flow manifold, the dangerous lean condition would more likely come from a lack of proper atomization to certain cylinders causing them to get a disproportionate amount of air to fuel, allowing some cylinders to run much leaner than others not due to airflow restrictions in the manifold, but due to lack of fuel in the airstream to those cylinders regardless of how much air they’re getting.

Test #1 (Baseline):

Stock Cast Iron Exhaust Manifolds and crappy crush bent tiny tube exhaust. Stock cast iron intake and Quadrajet Carb. This will strictly serve as a baseline for the stock motor/components.

- Dyno measured WHP/WTQ.

Test #1 Results:

Dyno: 158 WHP & 224 ft/lbs TQ

Other Notable Behavior:

Hard to cold start, best procedure seems to be to pump the fuel pedal 2-3 times, start the car, and then keep your foot lightly in the throttle while it warms up modulating the throttle for those first 10-15 seconds until it starts doing a little better. Drives pretty good though.

Test #2:

Summit Headers installed with 3″ dual exhaust and Flowmasters. Stock cast iron intake and Quadrajet Carb. EGT Probe in each cylinder with LC-1 Wideband in exhaust. MegaSquirt installed simply as a datalogging device monitoring manifold pressure and wideband o2.

- Dyno WHP/WTQ test to determine what power differences the exhaust modifications made.

- EGT and Wideband o2 monitoring to determine what AFR the engine is running at while at WOT, and more importantly what the air/fuel distribution looks like to each cylinder using the stock cast intake iron manifold and Quadrajet.

- Highway MPG test.

Test #2 Results:

Dyno: 176 WHP @ 255 ft/lbs TQ (+18 whp / +29 wtq)

Highway MPG: 14.3 MPG

Wideband: AFR is staying darn near stoich on the highway MPG tests, around 14.3-14.8:1. In the WOT pulls on the dyno AFR is between 12.9:1 and 13.5:1 which is fairly safe though maybe a bit on the lean side.

EGT: 200-250 degF differences between cylinders is common. This is fairly consistent whether cruising or making WOT pulls. Also it is very consistent which cylinders are high/low when under the same test conditions, but that changes when testing under different conditions.

See the charts below.

| Test2 EGT Results | |||||

| Cyl# | Cruise | Cyl# | |||

| 8 | 12.0% | 1438 | 1461 | 13.3% | 7 |

| 6 | 0.8% | 1276 | 1266 | 0.0% | 5 |

| 4 | 3.8% | 1316 | 1309 | 3.3% | 3 |

| 2 | 15.0% | 1489 | 1507 | 16.0% | 1 |

| Cyl# | WOT | Cyl# | |||

| 8 | 2.5% | 1399 | 1611 | 15.3% | 7 |

| 6 | 5.7% | 1447 | 1364 | 0.0% | 5 |

| 4 | 13.7% | 1580 | 1455 | 6.3% | 3 |

| 2 | 5.1% | 1438 | 1476 | 7.6% | 1 |

The Cruise Test (70mph) showed massive variance between cylinders, but with some commonality in how the cylinders were paired. i.e. The hottest two cylinders were right up front with 1 and 2. The second hottest pair were in the back with 7 and 8. The coolest cylinders, all with very acceptable variances of under 5%, are 3, 4, 5 & 6 right in the middle of the block. In every case, the cylinders matched left to right in how they stacked up hottest to coolest.

The WOT EGT test showed a very different story. It showed similar temperature variances between cylinders, but all of a sudden the cylinders that are acting up are all over the place. 5&8 are the coolest which aren’t across from each other, and the hottest cylinder of all, #7 is cornered by the two of the coolest. 1, 2 and 3 all run similar mid-range temps, but then there’s #4 right next to them running nearly as hot as #7. It’s as if under higher loads and faster moving air the turbulence causes very different things to happen in this manifold and the air/fuel distribution tells a very different story.

There should be concern for cylinders #4 and #7 if we were to disregard these issues and keep running them like this. The wideband showed 12.9:1 AFR at the low end of the WOT dyno pulls, and between 13.2:1 and 13.5:1 at the top end of the pulls (high rpm). On this naturally aspirated motor we want it between 12.6:1 and 13:1 AFR roughly. No richer, but not much leaner. What we have to consider is the wideband is averaging out the readings from all cylinders. I have the wideband currently monitoring one bank of cylinders, the even numbered 2,4,6,8. So let’s take the ‘mid-temp-range’ cylinders and call them normal. Meaning they’re the ones most likely to be closest to the AFR the wideband is reading. The cooler cylinders are richer, and the hotter cylinders are leaner, but how much? If the mid-temp-range cylinders really are at about 13.4:1 AFR, and our coldest to hottest cylinder difference is 15.3% difference, then that puts the coolest and hottest at about 7.65% each way from that middle of the road. This is conservative as the cooler cylinders on the WOT test were generally running only 5-6% cooler, while the hotter cylinders were running 9-10% hotter than the middle ground, but we’ll stick with the conservative 7.65% split of the total variance for this exercise.

IF (and we don’t know this for sure yet) the percentage of fuel required to cool a cylinder X percentage is equal to X also, and the tailpipe AFR was 13.4:1 as was on many of the WOT tests we ran here (and we saw worse) then on the hot cylinders, #4 and particularly #7, we’re running 7.65% LEANER than that 13.4:1. That’s 14.4:1 AFR, and that’s WAY TO LEAN FOR HIGH LOADS!

Other Notable Behavior:

Similar as the baseline Test1. Hard to cold start, best procedure seems to be to pump the fuel pedal 2-3 times, start the car, and then keep your foot lightly in the throttle while it warms up modulating the throttle for those first 10-15 seconds until it starts doing a little better. Drives pretty good though I can see it’s getting lean for an instant when I step into the throttle hard before it settles in.

Test #3 and #4:

Install ‘Performer’ Dual Plane Intake Manifold with stock Quadrajet carb. Also had in install a 3″ tall air filter element replacing the 4″ element we were using to correct some clearance issues.

- Dyno WHP/WTQ test to determine what power differences the exhaust modifications made.

- EGT and Wideband o2 monitoring to determine what AFR the engine is running at while at WOT, and more importantly what the air/fuel distribution looks like to each cylinder using the stock cast intake iron manifold and Quadrajet.

- Highway MPG test repeated.

Test #3 Results:

Dyno: 187 WHP @ 251 ft/lbs TQ (+11 whp / -5 wtq)

You need to read this Note. Test 3’s dyno results are only here as a comparison to test4 as the car was in the same configuration, but the dyno had to be reconfigured for the proper rear end ratio so we could read HP/TQ accurately. Basically test 1-3’s results are a bit high, test4 and on will be accurate.

Test #4 Results:

Dyno: 179.2 WHP @ 3600rpm / 334.7 ft/lbs TQ @ 1900rpm

The dyno is now properly calibrated for the axle ratio, this is the new baseline

Notice the power/torque falling on it’s face at 5200rpm, the AFR is so rich there the motor is missing badly and stumbling to rev on out. It eventually pulls through though, cleans up a bit and makes it out to 5500rpm. That explains that major dip and then the recovery right at redline.

Highway MPG: 18.36 MPG

Wideband: AFR is staying just barely rich of stoich on the cruise tests, mostly around 14.3-14.6:1. In the WOT pulls on the dyno AFR is around 12.4:1 at low rpm which would be just slightly rich of what I would target. BUT, then as the revs start to rise the AFR takes a dive towards crazy rich-land. By the midrange it’s in the low 11’s and it’s in the low 10’s by high rpm. Ending up at redline at about 10.0:1 flat. That’s insanely rich and we’re surely leaving a good bit of power on the table due to this. It’s also the reason for the misfires near redline causing the funky power curve up there.

EGT: Large temperature differences between cylinders is still common, but the story is a bit different with the Performer dual plane intake instead of the stocker. When cruising the cylinders are sortof all over the place, with some very large differences observable between cylinders, as much as 373 degF! Under WOT conditions, the story is pretty different, 6 of the 8 cylinders look much better with pretty tight temperature grouping, but cylinders 5 and 7 break the pattern, with 5 being a good 100 degF cooler than the group and 7 being about 200 degF hotter than the main grouping (that’s a 342 degF difference between the coolest and hottest cylinders 5 and 7).

One thing to note is the overall temperature differentiation is bigger now with the aftermarket manifold— we hadn’t seen anything bigger than a 16% differentiation between the hottest/coolest cylinder prior to the intake manifold upgrade. Now we’re seeing as much as 23.4%!

Here’s both the 70mph cruise (loaded on dyno) and ramp run pulls on one capture:

See the chart below:

| Test4 EGT Results | |||||

| Cyl# | Cruise | Cyl# | |||

| 8 | 20.0% | 1528 | 1595 | 23.4% | 7 |

| 6 | 13.6% | 1414 | 1222 | 0.0% | 5 |

| 4 | 10.1% | 1359 | 1420 | 13.9% | 3 |

| 2 | 19.8% | 1524 | 1586 | 23.0% | 1 |

| Cyl# | WOT | Cyl# | |||

| 8 | 9.4% | 1459 | 1664 | 20.6% | 7 |

| 6 | 9.4% | 1459 | 1322 | 0.0% | 5 |

| 4 | 6.0% | 1407 | 1466 | 9.8% | 3 |

| 2 | 8.8% | 1449 | 1474 | 10.3% | 1 |

Similar to Test2 with the stock manifold, the Cruise Test (70mph) showed massive variance between cylinders, but in this case the extremes were further apart in temperature with as much as a 366 degF temp difference between 5 and 7. It did still, for the most part, have some commonality in how the cylinders were paired as it did in test2 with the stock manifold, but with one exception— 5 and 6 are no longer paired, 6 is much hotter than 5 now. The air/fuel distribution to the cylinders with the Performer dual-plane intake is definitely worse than the stock manifold under cruise conditions.

The WOT EGT test again shows a very different story from the cruise test. But in this case it’s an improvement over the stock manifold. Whereas with the stock manifold in test2 under WOT the temps for the cylinders lost their grouping and were all over the place, with the Performer manifold under WOT the grouping is much improved, with 6 of the 8 cylinders (1,2,3,4,6 & 8) all pretty tightly grouped together, no more than 67 degF spread between them. The average temp of those 6 cylinders is 1452 degF. But then there’s cylinder 5, at 1322 degF, 230 degF cooler (about 9% cooler) and cylinder 7, at 1664 degF, 212 degF hotter than the average of the six, nearly 9% hotter than the average of that grouping.

There is still definitely room for concern for cylinder 7 being so much hotter than the other seven cylinders, which is an indication it’s that much leaner, running closer to stoich under full load where it needs to be richer, in the 13.0:1 range. But, that said, this manifold seems to be doing a much better job than the stocker at distributing air and fuel equally to most of the cylinders under WOT conditions, though it’s as slightly worse sway to the one hot cylinder with a larger temperature difference than the stock manifold allow to that one cylinder. Under cruise conditions, this manifold is all over the place with what appears to be fairly poor air/fuel distribution. I’d expect worse gas mileage.

Other Notable Behavior:

Similar as the baseline Test1. Hard to cold start, best procedure seems to be to pump the fuel pedal 2-3 times, start the car, and then keep your foot lightly in the throttle while it warms up modulating the throttle for those first 10-15 seconds until it starts doing a little better. Drives pretty good though I can see it’s getting lean for an instant when I step into the throttle hard before it settles in.

Test #5:

Install Holley Carb with Edlebrock Performer manifold

- Dyno WHP/WTQ test to determine what power differences the exhaust modifications made.

- EGT and Wideband o2 monitoring to determine what AFR the engine is running at while at WOT, and more importantly what the air/fuel distribution looks like to each cylinder using the stock cast intake iron manifold and Quadrajet.

- Highway MPG test repeated.

Test #5 Results:

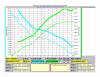

Dyno: 186.9 WHP @ 3950rpm / 337.1 ft/lbs TQ @ 1900rpm

On the dyno plot above, Test5 is the thick lines, Test4 is the thin lines for comparison. Notice how with this Holley, even in it’s base configuration, it’s not missing at the top end as much and completely dropping out like it was with the Quadrajet. The wideband shows why, it’s still a bit too rich to make optimal power up there, but it’s not nearly as rich as before so the ignition system is able to fire the mixture more consistently and it’s revving out much better.

Highway MPG: 18.56 MPG

Wideband: AFR is staying a bit rich on the cruise tests, mostly around 13.8-14.3:1, though we had the best fuel economy we’ve had yet with the Edlebrock Performer intake and Holley carb, there’s still room for improvement here with this too-rich AFR during cruise. If we can bring that back to 14.7 even, or even leaner to 15.3 or 15.5:1 at low-load cruise, we’ll save a few bucks on fuel.

In the WOT pulls on the dyno AFR is fluctuating a bit around 12:1 to 12.7:1 at low-mid rpms which isn’t that bad, I’d aim for about 12.6-12.8:1 so at times we’re a bit rich here, but at times it’s just right. Then as the revs start to rise the AFR gets richer, by 4600 it’s at 11.7:1 probably effecting power just a bit, and by redline the motor is running at about 11:1 which is rich enough to be down on power for sure.

EGT: Still having large temperature differences between cylinders, as much as 21.2% in these test results. See results and analysis below:

Here’s both the 70mph cruise and ramp run pulls:

See the chart below:

| Test5 EGT Results | |||||

| Cyl# | Cruise | Cyl# | |||

| 8 | 14.5% | 1543 | 1572 | 16.0% | 7 |

| 6 | 2.3% | 1351 | 1320 | 0.0% | 5 |

| 4 | 6.6% | 1413 | 1461 | 9.7% | 3 |

| 2 | 13.4% | 1524 | 1589 | 16.9% | 1 |

| Cyl# | WOT | Cyl# | |||

| 8 | 13.1% | 1493 | 1645 | 21.2% | 7 |

| 6 | 0.0% | 1297 | 1364 | 4.9% | 5 |

| 4 | 9.9% | 1439 | 1468 | 11.6% | 3 |

| 2 | 13.1% | 1493 | 1547 | 16.2% | 1 |

In summary, with the Holley we have better air/fuel distribution under cruise conditions than we did with the Quadrajet on the same manifold. However we can see in the EGT results for Test5 that during cruise the air fuel distribution still includes fairly massive temperature variation (279 degrees F to be exact). It’s better though, still not quite as good as the stock manifold and carb when working together (see Test2 EGT results)

The WOT EGT test with the Holley looks very different from Test4 with the Quadrajet. We now have a different cylinder (#6) that’s the coolest for the first time. We have a fairly tight grouping of cylinders 2, 3, 4, & 8. But cylinders 1 & 7 are running hot (read lean), and cylinders 5 & 6 are running cooler.

I’m still concerned about #7 being so hot (lean) though there was slight improvement with this setup. Overall Test5 made the most power we’ve seen yet with an improved air/fuel ratio even though the distribution was mucked up just a bit. Time for the single plane Torker II next…

Other Notable Behavior:

Installing the Holley cleared up the Hard Cold Start issue, it now starts right up and warms up when it’s cold. Unfortunately though, when it’s hot it doesn’t like to start so well and takes 2-3 tries sometimes for it to stay running if you try to restart it right after you’ve shut it down. The accelerator pump is setup a little better on the Holley for this motor and is helping to keep the initial lean spike down on acceleration. It has stalled a time or two due to a rich mixture at idle which I’ve corrected. Wouldn’t have been an issue except that’s really when the hot start issue becomes an issue, in traffic with a stalled car.

Test #6:

Install ‘Torker II’ Single Plane Intake Manifold with Holley carb

- Dyno WHP/WTQ test to determine what power differences the exhaust modifications made.

- EGT and Wideband o2 monitoring to determine what AFR the engine is running at while at WOT, and more importantly what the air/fuel distribution looks like to each cylinder using the stock cast intake iron manifold and Quadrajet.

- Highway MPG test repeated.

Test #6 Results:

Dyno: 187.5 WHP @ 4250rpm / 289.2 ft/lbs TQ @ 1900rpm (-47.9!)

On the dyno plot above, Test6 is the thick lines, Test5 is the thin lines for comparison. Just like you’ve been told, the single plane manifold falls on it’s face at low rpms with a nearly 50 ft/lb loss of torque, and then begins to shine at the top end with nice hp/torque increase, up until rich air/fuel mixture (and I suspect uneven air/fuel distribution) causes some ignition misfire and we lose power at around 5200rpm.

Highway MPG: 17.75 MPG Hwy.

Wideband: Not a big surprise we lost a bit of fuel economy with the Torker II intake as this it nowhere near it’s intended purpose. AFR is staying a bit richer on the cruise tests, averaging around 13.7:1. Fuel economy still wasn’t too bad considering but there is certainly room to improve.

In the WOT pulls on the dyno AFR is leaner at low-mid rpms with a brief lean spike to 15:1 or so and then back to more sane numbers of 12.7:1ish, working it’s way rich again as it approached redline and by redline getting to rich to sustain a reliable burn, blowing out the spark and causing a loss in power. It’s not any richer than it was with the Performer manifold at redline, but it’s blowing out spark worse for some reason. You can clearly see this in the EGT logs, look at the top end as we were approaching redline and you’ll see 6 of the eight cylinders suddenly ‘dip’ cooling down before we got out of it. That’s the spark blowing out and the results are no combustion hence cooler cylinder temps on those cylinders.

EGT: Temp difference between cylinders looks a bit better in the cruise tests, and much better in the WOT tests (samples taken around 5000rpm on WOT test):

Here’s both the 70mph cruise and ramp run pulls:

See the chart below:

| Test6 EGT Results | |||||

| Cyl# | Cruise | Cyl# | |||

| 8 | 14.1% | 1503 | 1549 | 16.7% | 7 |

| 6 | 5.0% | 1359 | 1291 | 0.0% | 5 |

| 4 | 7.7% | 1399 | 1384 | 6.7% | 3 |

| 2 | 13.6% | 1495 | 1516 | 14.8% | 1 |

| Cyl# | WOT | Cyl# | |||

| 8 | 7.5% | 1578 | 1524 | 4.3% | 7 |

| 6 | 0.0% | 1459 | 1532 | 4.8% | 5 |

| 4 | 6.5% | 1561 | 1601 | 8.9% | 3 |

| 2 | 2.7% | 1499 | 1645 | 11.3% | 1 |

So at cruise, we’ve got two fairly tight groupings, the inner four cylinders (3, 4, 5 and 6) with 6 being just a bit cool, and the outermost cylinders (1, 2, 7 & 8) with 7 being a bit hot. Not too surpising we’d see a pattern something like this looking at the Torker II’s single plane design. Overall the temp variance is a bit more in control than we’ve seen in a the last couple tests, though that’s still a 258degF temp difference from coolest to hottest. Number 7 is still a good bit leaner than the rest.

The WOT EGT test with the Holley and Torker II together has one of the tighest temp groupings yet. Really only cylinder #1 jumps significantly out of the grouping. Even #7, which has run hot in nearly all the tests this far, has been brought in line. We’ve got a 186degF variation from coolest to hottest, our smallest yet. The Torker II and Holley combo, at least compared to the other items we’ve tested this far, seem to flow the most evenly overall.

Other Notable Behavior:

Same behavior as test5, only difference is now I have no bottom end torque with this manifold.

Installing the Holley cleared up the Hard Cold Start issue, it now starts right up and warms up when it’s cold. Unfortunately though, when it’s hot it doesn’t like to start so well and takes 2-3 tries sometimes for it to stay running if you try to restart it right after you’ve shut it down. The accelerator pump is setup a little better on the Holley for this motor and is helping to keep the initial lean spike down on acceleration. It has stalled a time or two due to a rich mixture at idle which I’ve corrected. Wouldn’t have been an issue except that’s really when the hot start issue becomes an issue, in traffic with a stalled car.

Test #7:

Install GM Rochester TBI onto Torker II single-plane Intake Manifold, using electric fuel pump

EMS Used – MegaSquirt-I PCBv3.0 running MS1-Extra Firmware version 029y4

Test #7 Results:

Test aborted and will need to retest. FPR in TBI needed to be rebuilt causing unstable results, didn’t realize this was root cause until I had already swapped manifolds for test8.

Test #8:

Install GM Rochester TBI onto Performer dual-plane Intake Manifold, using electric fuel pump

EMS Used – MegaSquirt-I PCBv3.0 running MS1-Extra Firmware version 029y4

Test #8 Results:

Dyno: 184.3 WHP @ 3800rpmn / 342.6 ft/lbs TQ @ 1900rpm

(First image is test8 by itself, second is compared to test5)

Compared to test5 (same intake with Holley 600 carb) this is a nice gain in low end torque and a small whp decrease – by 2.6whp at peak. The HP and Torque curve look very similar with the main difference being the Test8 curve with the smaller TBI starts to fall off a bit earlier than the larger Holley did, causing that 2.6whp peak drop.

This is working out pretty good actually. Still not getting perfect air/fuel distribution, but we weren’t with the carb either. I have been able to get fairly good power numbers with the TBI un-modified however. Bear in mind this is a stock GM 5.7l TBI that’s designed to flow about 480 cfm. We took it a step further and added the common ‘TBI Spacer’ which just places the injectors a tad higher in the airstream and that helped a eek a bit more airflow out of the unit making slightly better numbers than the unmodified unit (maybe 3-4whp). For a low flow two barrel design it’s hanging in there pretty good with the 4 barrel 600cfm Holley in the WHP department considering the air flow limitation. A bit more torque on the bottom end, less midrange and top end until right at redline when the TBI pulls ahead again.

The car runs great, fires up and warms up on a cold day much better than any of the carb solutions did. Drives great with no hesitations, surges, etc. But (yes there’s a but) I’m having to keep it a bit richer than I’d like due to air/fuel distribution being a bit less than ideal. If I lean it out too much there are a couple cylinders that are fuel starved (too lean) and start to misfire. The problem here is possibly the intake manifold and TBI adapter, with the manifold being designed for a four-barrel carb it may just not distribute fuel as well with the two barrel sitting on the adapter in the middle of the carb flange. That’s one possibility. Another is the EMS may need to control injector pulsewidth to a finer resolution, allowing a finer level of control over the amount of fuel sprayed on each squirt. With only two fairly large injectors feeding 8 cylinders this could be exaggerated a bit as those squirts are shared, if one cylinder draws air and grabs all of one, then next cylinder maybe be starved for fuel. Sortof the same situation you’d find yourself in trying to put multiport injection on a siamese port engine (that’s another project though). So what do we do? I could load the MS1 Extra ‘Hi-Res’ firmware on this MS-1 ECU to control the injectors to a finer resolution, but I’d need a resistor pack as the Hi-Res firmware sacrifices Low-Impedance injector support and these are low-z injectors. Or better yet, I can upgrade this installation with an MS-II daughterboard, get much finer injector pulsewidth resolution (100x more) and also have the ability to control my stepper idle speed motor on this TBI. This is what I’d recommend for my customers anyways, even if the injector PW resolution wasn’t needed the stepper idle control is something most would want, I just choose to do things the hard way for some reason most of the time. So on the next test we’ll see if this helps any. If not I’ll grab an intake manifold designed for use with a TBI.

Highway MPG: Not Tested — probably would have been the same or maybe even worse than some of the prior solutions until we sort out the air/fuel distribution as we were running it a bit rich to compensate.

Other Notable Behavior:

Starts and runs good, fires right up when it’s cold though sometimes I’m still babying it with the throttle a little for those first few seconds. I haven’t hooked the Stepper IAC up yet so the computer can’t control the idle when cold to assist with warmup. I’ll need to upgrade to MS-II to do this which was the plan. Driveability of the car is excellent though, jump on it and it goes. Good low end torque, feels stronger than before and the numbers give the TBI a slight edge, but it’s pretty much a tie with the Holley for low end grunt. The loss of 2.6 peak whp won’t effect me at all unless I manually shift this car as the stock TH-350 tranny doesn’t let it get above 3800-3900rpm or so before it shifts. Looking forward to trying the MS2, getting the IAC working, leaning it out a bit, and having a nice cruiser here.

Test #9:

Running GM Rochester TBI on Performer dual-plane Intake Manifold, using electric fuel pump, (same hardware as test8). EMS upgraded to MS-II and Fuel Pump swapped out to Walbro 255lph unit (GSL392)

EMS Used – MegaSquirt-II PCBv3.0 running MSII version 2.888 firmware (standard B&G code)

Test #9 Results:

We’re getting much better air/fuel distribution with this configuration. The engine is running very smooth.

Dyno: 180.1 WHP @ 4250rpm / 289.2 ft/lbs TQ @ 1900rpm

Test #11:

Holley 900 cfm Pro-Jection TBI on Performer dual plane intake manifold. Other hardware same as test 9.

EGTs at WOT on dyno:

Cyl 1: 1732

Cyl 2: 1663

Cyl 3: 1614

Cyl 4: 1549

Cyl 5: 1505

Cyl 6: 1372

Cyl 7: 1707

Cyl 8: 1672

Similar general pattern, outboard cylinder running leaner and inboard ones running richer. Seems to be a characteristic of this manifold.