Updated September 2022 by Jerry Hoffmann

Chapter 4: Electronic Fuel Injection Options – Throttle Body Injection (TBI), MultiPort Fuel Injection (MPFI), Sequential Point Fuel Injection (SPFI), and Direct Injection (DI)

What is your starting point– Factory EFI Takeover? Or Carb-to-EFI Conversion?

First off, let’s discuss the different people and perspectives that you’re approaching this from. Some of you are taking control of a factory EFI car. Some of you are converting an engine that was never intended to have EFI on it, from a carb over to EFI. This guide aims to meet both of you where you are at, but it’s fair to call out, you’re starting from very different places!

Welcome to those of you in the Factory EFI Takeover Crew!

Some of you will be starting from a foundation. You’re taking control of an engine that came from the factory with an OEM/Factory Electronic Fuel Injection System already already in place on the engine you’re using in your project. In some cases, you’re using that engine in the car/truck that it came in from the factory. In other cases, you’re using an engine you’ve transplanted from another vehicle into your project, be it a classic street rod, a budget car you’re doing some weekend warrior racing in, or a full on max effort race car built with one thing in mind– maximum performance. In many cases, you may have no need to fully architect a new EFI system or Ignition system design from what the factory had in place. You may CHOOSE to in some cases however, based on your goals for the vehicle and the power you plan to make, but in many cases you can reuse much of what’s already there and just take control of it all. We’ll call you the OEM EFI Takeover Crew. You’ve got many of the pieces in place that you can very likely re-use, depending on your goals. Sensors, the fuel system, and more can in most cases be re-used. If you’re going big on power, you might have to make a few upgrades, maybe a bigger fuel pump for example. But you’re starting from a very different point with less to consider than a carb-to-efi conversion.

You too, Carb-To-EFI Conversion Crew! This series is definitely for you as well!

Some of you however, are starting from a blank slate. Don’t let this be scary, it’s really not, it’s a lot of fun modernizing some old iron with EFI! Maybe you’re working with a 350 Small Block Chevy or 289 Small Block Ford or an old school Big Block motor, all of which almost surely did NOT come from the factory with EFI/Fuel Injection. They came with a carburetor, or in some cases multiple carburetors. On the ignition side, they more than likely came with a single coil and distributor (in some rare cases, two distributors). That distributor may have been points based, or may have been a slightly more modern HEI type or similar. We’ll refer to you in this series as our Carb-To-EFI Conversion Crew.

No matter which of these two ‘Crews’ you’re a part of, this chapter will help you to understand the different types, or topologies, of Electronic Fuel Injection Control that are available to you.

If you’re a Carb-To-EFIer, you have a clean slate and you get to CHOOSE exactly what sort of system you’ll want to install. TBI aiming for simplicity and/or a somewhat carb-like appearance? Simple Bank or Batch fire MPFI? Or all the way to Sequential Injection? We’ll provide you with the information you need to be able to make an educated decision based on the pros and cons of each system.

If you’re an OEM EFI Takeover-er, you have components in place already that can be reused. Maybe you’re working on a early 1990’s 4.3 Chevy, or small block V8 with a TBI EFI System. You can use that as is, or you can make a change. Maybe you’re working with an early Multi-Port Fuel Injection system that uses a bank-fire or batch-fire approach, firing either all, or multiple, injectors at the same time. You can run that just as the factory did, or fairly easily convert to Sequential Point Fuel Injection (SPFI) with what may likely only require a little wiring change to the injectors and the addition of a Camshaft Position Sensor. Your question then becomes ‘will the factory style of injection meet my needs?’, and we’ll help you to answer that below and in the following chapters.

So what are the major types of EFI systems to consider?

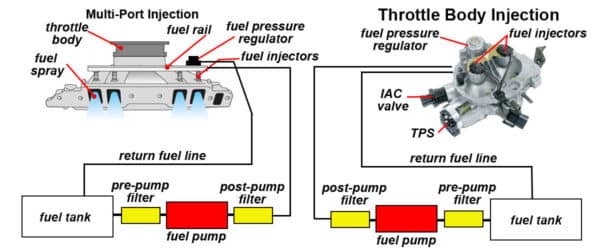

There are really two main categories here. TBI and MPFI. To a degree, this can kindof be thought of as an overhead view of the system. How many components are there, where are they, why are they there, and what are the pros and cons of each system?

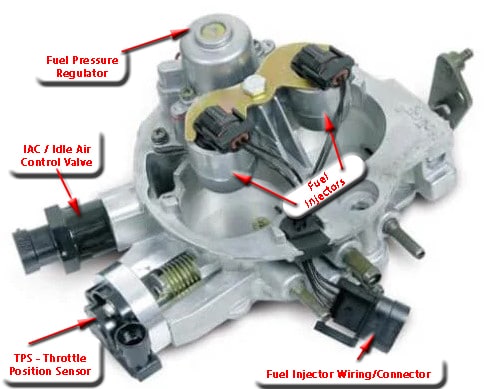

TBI – Throttle Body Injection:

Why is this acceptable for the Factory OEM EFI Takeover Crew?

You’re already using the factory Throttle Body. The factory Intake Manifold. And the factory Cylinder Heads. These three components make up an INDUCTION SYSTEM that was factory engineered, designed, and tuned to work together as a system to deliver fuel reasonably evenly to each cylinder under the various operating conditions the motor would be operated at. It works reasonably well, not amazing, but reasonably well. Start changing things, and the story can change rapidly.

Why is this often less than ideal for the Carb-To-EFI Crew?

Ultimately there are several challenges that make a Carb-to-TBI Fuel Injection conversion less than ideal. I know there are vendors that will point you this direction, and if your expectations are low, they’ll probably meet them! But my expectations are not low. And I’ve tried it. I’ve tested and tuned on the dyno and driven them on the street/track, and well, it’s just not the upgrade you’re looking for. I get it, it’s simple in operation it appears, and there are aftermarket companies selling aftermarket ‘kits’ that claim to ‘just work’ and to even tune themselves! Some of you will go this route against my advice, and that’s ok. Many of you who do will live to regret it, and will later change to MPFI after experiencing what I have. I’ve done extensive testing with a variety of OEM and Aftermarket TBI units, and I’ve heard from a multitude of customers that have gone down this path either using OEM or Aftermarket TBI systems. I’ve spent many hours on our dyno testing and tuning, hundreds of miles on the road looking for improved drivability and fuel consumption. And in all of my testing, and everything I hear most consistently from others that have tried this as well…. the results are not what you are looking for when converting from a Carburetor to EFI. You’ll likely see some positives, tunability and maybe easier start-up, but many negatives, such as fuel economy that at best is similar to the carb, and could even be worse.

Why is this? Why is TBI less than ideal for most Carb-To-EFI conversions?

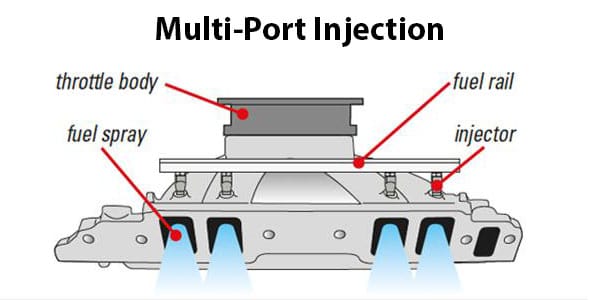

MPFI – MultiPort Fuel Injection or Multi Point Fuel Injection :

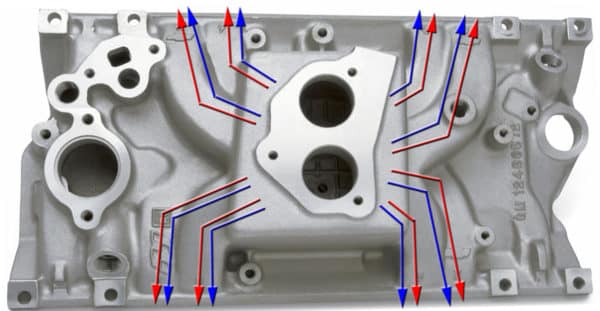

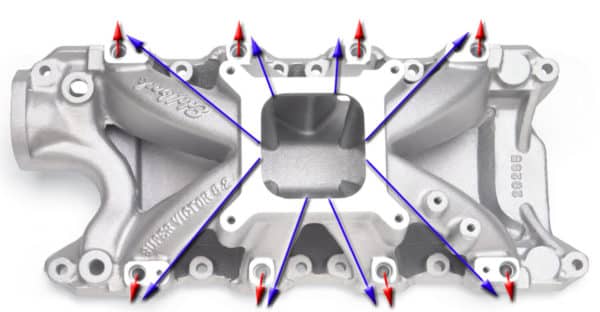

MPFI, or MultiPort Fuel Injection, has been the dominant method of EFI fuel injection and distribution for more than 30 years now. And with good reason. Even the simplest of these systems, which are reasonable easy to adapt to most any engine, are superior to TBI when it comes to proper and even air and fuel distribution to each cylinder. There are several different sub-types that could all be classified as MPFI, as as it’s core Multi PORT Fuel Injection, or Multi POINT Fuel Injection, delivers the fuel NOT before the throttle body, but after it, into each individual intake runner. ITBs almost fall into a call of their own in some cases, as they can inject fuel before or after the throttle blades, but in general ITB (Individual Throttle Bodies) have much more in common with MPFI than with TBI, injecting the fuel along the path to a dedicated intake runner tied to a specific single cylinder. (EFI on Siamese port engines which share an intake runner for each pair of cylinders are another discussion, we’ll touch on that below– it can be done, and done well!)

Batch Fire MPFI:

You can also operate a Batch Fire MPFI system with multiple injector drivers. Using again the example of a V8 engine, you could hang four fuel injectors off of one ECU injector output for one side of the engine, and hang the other four off of another ECU Injector Output. Or four injectors outputs controlling two injectors each.

The differentiating factor of Batch Injection to other types of MPFI Fuel Injection detailed below, is that with Batch Injectors, regardless of how many injectors you’re using and how many injector outputs/injector drivers they are connected to at the ECU– ALL FIRE AT THE SAME TIME. There is no alternating injection events.

It should be noted that Batch MPFI Injection can be triggered with a very simple ignition system. The ECU only needs to know what the engine speed is, not which part of the engine cycle you’re on. It doesn’t care if you’re on the Intake, Compression, Power, or Exhaust stroke of the piston. It’s just keeps spraying fuel. Typically that means you can trigger the ECU’s Tach/RPM Input with a simple distributors points output, or off the negative terminal of the ignition coil, or off of a crank trigger. And you can use a cam trigger input also if you want, but you wouldn’t be taking full advantage of it. Which is OK… and could be done intentionally as part of a plan to convert to Bank or Sequential EFI later!

Bank Fire MPFI:

Bank Fire MultiPort Fuel Injection is really just a small twist on Batch Fire MPFI. This will therefore be a very short section! In short… the difference is, though you could be using as many as one per cylinder, you are ALWAYS using at least two injector outputs from your ECU, and you’re firing the injectors in a Bank-to-Bank fashion. Alternating. One injector output fires (and all of the injectors on that output ‘squirt some fuel) and then the other fuel injector output and injectors fire.

Typically these are most commonly wired in a left/right bank-to-bank fashion. On a V engine, all cylinders on one side fire on one injector output, and all of the cylinders on the other side fire together on the other output. This can have a moderate improvement on fuel rail pressure consistency since not all injectors on both sides fire at the same time, but it’s still fire all of the injectors on a given fuel rail, so it’s not perfect. It’s better. Sequential addresses this in all but the most extreme cases, and it’s usually not a huge problem anyways unless your injectors are massive or your fuel system is inadequate.

Most everything else I wrote in the Batch section still applies. A simple ignition/crank trigger only showing the ECU the engine RPM/speed is all you need. If you wire your injectors discretely and use an EMS like the MS3Pro capable of control and tuning of each injector individually, you can fine tune your fuel per cylinder, all the same as above.

SPFI – Sequential Port Fuel Injection (aka Sequential Point Fuel Injection):

Ahhh…. Sequential Port Fuel Injection. This is kindof the sweet spot where you get all of the drivability, performance, economy, and emissions that you’re looking for. It requires ONE more sensor is all, as compared to Batch or Bank Injection. That would be a Camshaft Position Sensor (CPS), also known as a Cam Angle Sensor (CAS), or even a ‘Cam Sync’.

The Crankshaft Position Sensor tells the ECU what speed the engine is operating at, in RPM. It does this with a series of ‘teeth’ on a trigger wheel, often these teeth quite frankly look like, well, teeth! Sometimes though they could be in the form of magnets using a Hall Sensor, or even ‘holes’ in a trigger wheel disc using an optical sensor to pass and detect light through the holes as the disc spins.

You’ll also need a Cam Angle Sensor. Typically this is a trigger wheel that operates at Cam speed, with a single ‘tooth’ that tells the ECU which engine cycle your on at any given time.

We’ll get into a deeper discussion of this later in Chapter 7, so don’t bet bogged down in it now. Just know that in order to fire the fuel injectors (and for that matter, the ignition coils) sequentially, meaning ONE injection event per injector on each engine cycle, generally right before the intake valve opens – you will need a crank and cam trigger. It it’s simplest for, you can use a simple dual-sync CAS or distributor to provide this, which has a crank and cam wheel that both operate at cam speed. Maximum accuracy is possible with a separate crank trigger wheel and cam angle sensor.

That CAS, or Cam Angle Sensor, is the only major difference between having what it takes to run Batch/Bank Injection versus running Sequential Fuel Injection. And all of the other positives you’ve seen above, the ability to fine tune each cylinder to account for different airflow to each cylinder through the intake manifold for example still applies. You’re discretely controlling the fuel injectors from that MS3Pro ECU and you have the power to tune with excellence!

ITB – Individual Throttle Body Injection

Max effort naturally aspirated tuners tend to love these things. Much more even air distribution is possible assuming the intake manifold is well designed. You could control the injectors, I suppose, in a Bank or Batch fashion, but you probably wouldn’t. Typically ITBs are operated sequentially, and if there are any differences per cylinder to the airflow, they are minimal and can be accounted for with individual cylinder tuning. Oh, and they sound AMAZING!!!

DI – Direct Injection:

And finally, we get to Direct Injection. The latest most current Fuel Injection approach used on many factory/OEM vehicles leaving the showroom floor today, unlikely to be turned into race cars for a number of years yet perhaps.

Direct Injection was designed to reach government mandated emissions and fuel economy goals, and it can certainly help to do that. The Induction System in this case is more than just the intake manifold, and intake runner of the cylinder head, but also includes unique and critical engineering of the cylinder head’s combustion chamber and even the piston top itself! It’s had some teething issues along the way but they are making improvements, and for the most part, as it is emissions/economy focused and only available on the newest of vehicles, is not all that commonly seen in the performance/racing automotive aftermarket. And without any significant performance gains unlocked, it just hasn’t caught on for most due to added complexity. Unless of course they’re trying to mod a brand new vehicle, but even in that case, many opt for a SPFI system running in conjunction with the DI system to add any additional fuel that’s needed. That’s a perfectly workable solution that many have had success with.

At this time, this guide won’t delve too deep into Direct Injection, perhaps in a future installment we’ll address this in greater detail.

Thanks for checking out this comparison and explanation of different EFI control methodologies.

We’ve discussed TBI vs Bank vs Batch vs Sequential MPFI vs DI and even ITBs. Whew! That was a lot things to versus! Stay tuned! More awesome EFI tech info is incoming!

>>> Read Chapter 5A: Understanding the EFI Fuel System: Overview >>>

<<< Go Back to Chapter 3: Garbage In, Garbage Out: The Three Stages of Success <<<

*** Return to the Table of Contents ***

Click Here to check out our MADE IN THE USA Engine Management Systems!

Copyright 2022 Hoffmann Innovations Inc. aka DIYAutoTune.com