Description

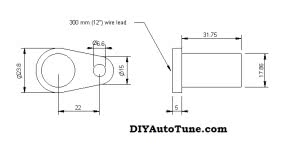

Crank Position Sensor – Hall Effect tab mount

Hall effect crank position sensor (or camshaft position sensor, or wheelspeed, or driveshaft speed, anything that spins!). We’ve tested this with our 6.75″ and 8.25″ trigger wheels. We were able to get a rock solid reading at over 19,200 RPM, which is as fast as our test rig could spin the trigger wheel. Runs off 5 to 24 volts, and gives a nice square wave so there’s no variable voltage issues. Has a 12 inch long, 3 wire pigtail. Here’s what the wires do:

Installation Info:

- Red – Supply voltage; connect to either VREF or 12 volt switched power.

- White – Output signal. On a MegaSquirt V3.0 or V3.57, connects to pin 24. We just set our MegaSquirt up for the VR conditioner and it works great. V3.0 MicroSquirts can also accept this signal over their VR conditioner input, but older MicroSquirts will need to use the Hall effect input.

- Black – Ground.

Using the current revision of our ECU wiring harnesses, you can just tee the red wire on this crank position sensor into the red harness wire, and the black and white wires connect to the respective black and white wires inside the shielded RPM input wire. Red to red, black to black, white to white – simple and easy to remember.

Specifications

- Ideal uses

- Crank Position Sensor

- Cam Position Sensor

- Wheelspeed Sensor

- Driveshaft speed Sensor

- Operating voltage: 4.75 to 24 volts

- Maximum overvoltage and reverse voltage: +27 to -25 volts

- Maximum output current: 20 mA

- Maximum frequency: 15 kHz

- Temperature range: -40 to +125 degrees C

- Maximum air gap: 5 mm

- Note that this is an absolute maximum. For most trigger wheels, operation is most reliable at a 1.0 to 1.5 mm air gap.

- The trigger wheel must be at least 2 mm wide, the teeth and gaps at least 2 mm wide, and the gaps at least 2 mm deep.

Note: We also carry a threaded body crankshaft position sensor- click HERE.

12 reviews for Crankshaft / Camshaft Position Sensor – Hall Effect tab mount